2025

|

Qiao, Y.; Grad, M.; Nonn, A. Toward an Efficient and Robust Process–Structure Prediction Framework for Filigree L-PBF 316L Stainless Steel Structures Werkstoffsimulation Artikel In: Metals, Bd. 15, Nr. 7, 2025, ISSN: 2075-4701. @article{Qiao2025,

title = {Toward an Efficient and Robust Process–Structure Prediction Framework for Filigree L-PBF 316L Stainless Steel Structures},

author = {Y. Qiao and M. Grad and A. Nonn},

doi = {10.3390/met15070812},

issn = {2075-4701},

year = {2025},

date = {2025-07-00},

urldate = {2025-07-00},

journal = {Metals},

volume = {15},

number = {7},

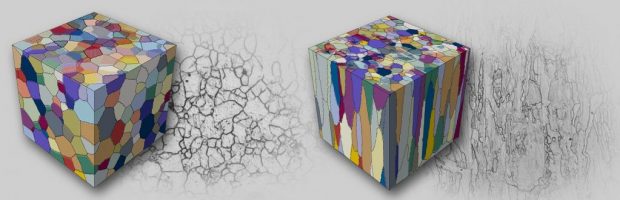

publisher = {MDPI AG},

abstract = {Additive manufacturing (AM), particularly laser powder bed fusion (L-PBF), provides unmatched design flexibility for creating intricate steel structures with minimal post-processing. However, adopting L-PBF for high-performance applications is difficult due to the challenge of predicting microstructure evolution. This is because the process is sensitive to many parameters and has a complex thermal history. Thin-walled geometries present an added challenge because their dimensions often approach the scale of individual grains. Thus, microstructure becomes a critical factor in the overall integrity of the component. This study focuses on applying cellular automata (CA) modeling to establish robust and efficient process–structure relationships in L-PBF of 316L stainless steel. The CA framework simulates solidification-driven grain evolution and texture development across various processing conditions. Model predictions are evaluated against experimental electron backscatter diffraction (EBSD) data, with additional quantitative comparisons based on texture and morphology metrics. The results demonstrate that CA simulations calibrated with relevant process parameters can effectively reproduce key microstructural features, including grain size distributions, aspect ratios, and texture components, observed in thin-walled L-PBF structures. This work highlights the strengths and limitations of CA-based modeling and supports its role in reliably designing and optimizing complex L-PBF components.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

Additive manufacturing (AM), particularly laser powder bed fusion (L-PBF), provides unmatched design flexibility for creating intricate steel structures with minimal post-processing. However, adopting L-PBF for high-performance applications is difficult due to the challenge of predicting microstructure evolution. This is because the process is sensitive to many parameters and has a complex thermal history. Thin-walled geometries present an added challenge because their dimensions often approach the scale of individual grains. Thus, microstructure becomes a critical factor in the overall integrity of the component. This study focuses on applying cellular automata (CA) modeling to establish robust and efficient process–structure relationships in L-PBF of 316L stainless steel. The CA framework simulates solidification-driven grain evolution and texture development across various processing conditions. Model predictions are evaluated against experimental electron backscatter diffraction (EBSD) data, with additional quantitative comparisons based on texture and morphology metrics. The results demonstrate that CA simulations calibrated with relevant process parameters can effectively reproduce key microstructural features, including grain size distributions, aspect ratios, and texture components, observed in thin-walled L-PBF structures. This work highlights the strengths and limitations of CA-based modeling and supports its role in reliably designing and optimizing complex L-PBF components. |

2024

|

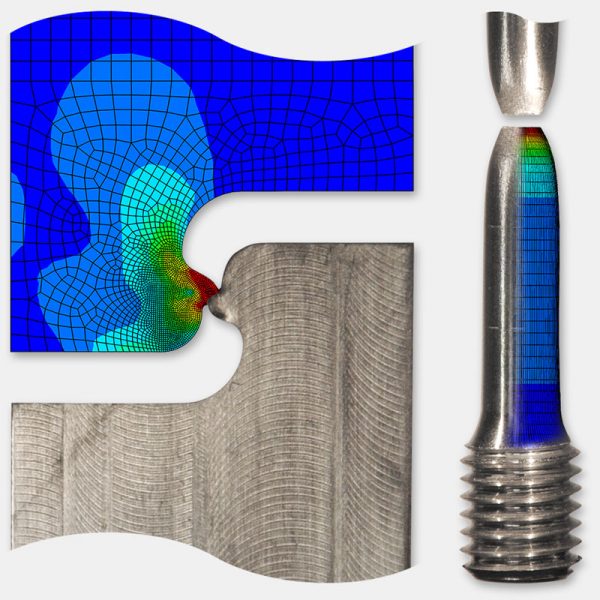

Nonn, A.; Marx, P. Validated Multiphysics Modeling For Advanced Pipeline Integrity Management Werkstoffsimulation Konferenz ADIPEC, November 4–7, 2024, Abu Dhabi, UAE, 2024. @conference{Nonn2024,

title = {Validated Multiphysics Modeling For Advanced Pipeline Integrity Management},

author = {A. Nonn and P. Marx},

doi = {10.2118/222279-ms},

year = {2024},

date = {2024-11-04},

urldate = {2024-11-04},

publisher = {ADIPEC, November 4–7, 2024, Abu Dhabi, UAE},

abstract = {The aim of this paper is to present practical steps for utilizing a validated multiphysics approach for fracture control in CO2 pipelines within the framework of Carbon Capture Transport and Storage (CCTS). Ensuring the arrest of running ductile fracture (RDF) is a crucial safety requirement for the transportation of dense-phase CO2. However, current standards rely on outdated and restrictive methods, imposing severe limitations on pipeline material and structural design. As a result, projects that fall outside these standards face the need for extremely costly tests, often leading to delays or cancellations of CCTS initiatives. This study introduces an advanced, validated, fully-coupled fluid-structure interaction (FSI) model designed to accurately predict fracture propagation in CO2 pipelines. A key advantage of this approach is its use of robust and reproducible calibration and validation procedures combined with high-quality material characterization data. The full coupling of structural, fluid, and backfill models is essential for obtaining precise results, not only in determining arrest occurrence but also in analyzing properties such as fracture velocity history, 3D pressure distributions behind the propagating crack, wall thinning, and crack tip opening angle. The FSI model has demonstrated its value as a cost-effective tool for safety assessments, enabling the development of fracture control plans that specify minimum required material properties and fluid compositions for optimized pipeline design, both onshore and offshore. Additionally, performing virtual studies with the parameterized FSI model enables the generation of synthetic data for training and validating a machine learning surrogate model. This surrogate model can be integrated into industrial practices, facilitating the application of multiphysics modeling without the need for extensive expertise.},

keywords = {},

pubstate = {published},

tppubtype = {conference}

}

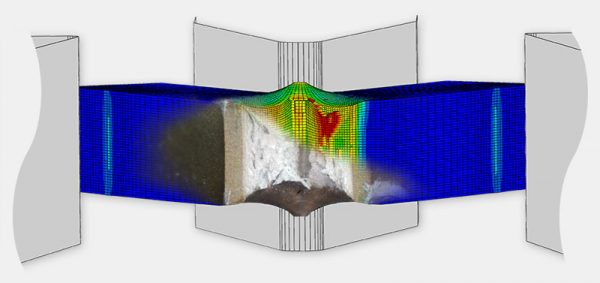

The aim of this paper is to present practical steps for utilizing a validated multiphysics approach for fracture control in CO2 pipelines within the framework of Carbon Capture Transport and Storage (CCTS). Ensuring the arrest of running ductile fracture (RDF) is a crucial safety requirement for the transportation of dense-phase CO2. However, current standards rely on outdated and restrictive methods, imposing severe limitations on pipeline material and structural design. As a result, projects that fall outside these standards face the need for extremely costly tests, often leading to delays or cancellations of CCTS initiatives. This study introduces an advanced, validated, fully-coupled fluid-structure interaction (FSI) model designed to accurately predict fracture propagation in CO2 pipelines. A key advantage of this approach is its use of robust and reproducible calibration and validation procedures combined with high-quality material characterization data. The full coupling of structural, fluid, and backfill models is essential for obtaining precise results, not only in determining arrest occurrence but also in analyzing properties such as fracture velocity history, 3D pressure distributions behind the propagating crack, wall thinning, and crack tip opening angle. The FSI model has demonstrated its value as a cost-effective tool for safety assessments, enabling the development of fracture control plans that specify minimum required material properties and fluid compositions for optimized pipeline design, both onshore and offshore. Additionally, performing virtual studies with the parameterized FSI model enables the generation of synthetic data for training and validating a machine learning surrogate model. This surrogate model can be integrated into industrial practices, facilitating the application of multiphysics modeling without the need for extensive expertise. |

Marx, P.; Nonn, A. Advancing CO2 Pipeline Safety: Innovative Predictive Approaches and their Application in On- and Offshore Ductile Fracture Assessment Werkstoffsimulation Proceedings Article In: Proceedings of Pipeline Technology Conference 2024, 2024, ISSN: 2510-6716. @inproceedings{marx_advancing_2024,

title = {Advancing CO2 Pipeline Safety: Innovative Predictive Approaches and their Application in On- and Offshore Ductile Fracture Assessment},

author = {P. Marx and A. Nonn},

issn = {2510-6716},

year = {2024},

date = {2024-04-01},

urldate = {2024-04-01},

booktitle = {Proceedings of Pipeline Technology Conference 2024},

abstract = {In the pursuit of Carbon Capture and Storage (CCS) initiatives, the establishment of an extensive network of transportation pipelines, encompassing both on- and offshore domains, becomes paramount. A crucial aspect of ensuring the integrity of these pipelines is the assessment of running ductile fractures (RDF), a phenomenon in which defects evolve into cracks driven by pressure forces from escaping mixtures. While the Battelle Two-Curve Method (BTCM) is widely used for RDF assessment, it was originally designed for natural gas and proves inadequate for CO2 applications. Existing international guidelines, such as ISO 27913 and DNVGL-RP-F104, still rely on this method, resulting in uncertainties and potentially uneconomical designs due to excessive safety margins. This paper addresses the gap by introducing a cost-effective assessment approach utilizing a recently developed and validated Fluid-Structure Interaction (FSI) model. This model incorporates the coupled prediction of CO2 mixture decompression behavior during crack propagation in pipelines. Notably, the numerical FSI model accurately predicts results from different full-scale experiments, encompassing 3D decompression and crack arrest behavior in pipelines, both onshore and offshore. This advancement offers a promising path toward enhancing CO2 pipeline safety and facilitating the transition to sustainable energy solutions.},

keywords = {},

pubstate = {published},

tppubtype = {inproceedings}

}

In the pursuit of Carbon Capture and Storage (CCS) initiatives, the establishment of an extensive network of transportation pipelines, encompassing both on- and offshore domains, becomes paramount. A crucial aspect of ensuring the integrity of these pipelines is the assessment of running ductile fractures (RDF), a phenomenon in which defects evolve into cracks driven by pressure forces from escaping mixtures. While the Battelle Two-Curve Method (BTCM) is widely used for RDF assessment, it was originally designed for natural gas and proves inadequate for CO2 applications. Existing international guidelines, such as ISO 27913 and DNVGL-RP-F104, still rely on this method, resulting in uncertainties and potentially uneconomical designs due to excessive safety margins. This paper addresses the gap by introducing a cost-effective assessment approach utilizing a recently developed and validated Fluid-Structure Interaction (FSI) model. This model incorporates the coupled prediction of CO2 mixture decompression behavior during crack propagation in pipelines. Notably, the numerical FSI model accurately predicts results from different full-scale experiments, encompassing 3D decompression and crack arrest behavior in pipelines, both onshore and offshore. This advancement offers a promising path toward enhancing CO2 pipeline safety and facilitating the transition to sustainable energy solutions. |

2023

|

Nonn, A.; Kiss, B.; Pezeshkian, W.; Tancogne-Dejean, T.; Cerrone, A.; Kellermayer, M.; Bai, Y.; Li, W.; Wierzbicki, T. Inferring mechanical properties of the SARS-CoV-2 virus particle with nano-indentation tests and numerical simulations Werkstoffsimulation Artikel In: Journal of the Mechanical Behavior of Biomedical Materials, Bd. 148, 2023, ISSN: 1751-6161. @article{Nonn2023,

title = {Inferring mechanical properties of the SARS-CoV-2 virus particle with nano-indentation tests and numerical simulations},

author = {A. Nonn and B. Kiss and W. Pezeshkian and T. Tancogne-Dejean and A. Cerrone and M. Kellermayer and Y. Bai and W. Li and T. Wierzbicki},

doi = {10.1016/j.jmbbm.2023.106153},

issn = {1751-6161},

year = {2023},

date = {2023-12-00},

urldate = {2023-12-00},

journal = {Journal of the Mechanical Behavior of Biomedical Materials},

volume = {148},

publisher = {Elsevier BV},

abstract = {The pandemic caused by the SARS-CoV-2 virus has claimed more than 6.5 million lives worldwide. This global challenge has led to accelerated development of highly effective vaccines tied to their ability to elicit a sustained immune response. While numerous studies have focused primarily on the spike (S) protein, less is known about the interior of the virus. Here we propose a methodology that combines several experimental and simulation techniques to elucidate the internal structure and mechanical properties of the SARS-CoV-2 virus. The mechanical response of the virus was analyzed by nanoindentation tests using a novel flat indenter and evaluated in comparison to a conventional sharp tip indentation. The elastic properties of the viral membrane were estimated by analytical solutions, molecular dynamics (MD) simulations on a membrane patch and by a 3D Finite Element (FE)-beam model of the virion's spike protein and membrane molecular structure. The FE-based inverse engineering approach provided a reasonable reproduction of the mechanical response of the virus from the sharp tip indentation and was successfully verified against the flat tip indentation results. The elastic modulus of the viral membrane was estimated in the range of 7–20 MPa. MD simulations showed that the presence of proteins significantly reduces the fracture strength of the membrane patch. However, FE simulations revealed an overall high fracture strength of the virus, with a mechanical behavior similar to the highly ductile behavior of engineering metallic materials. The failure mechanics of the membrane during sharp tip indentation includes progressive damage combined with localized collapse of the membrane due to severe bending. Furthermore, the results support the hypothesis of a close association of the long membrane proteins (M) with membrane-bound hexagonally packed ribonucleoproteins (RNPs). Beyond improved understanding of coronavirus structure, the present findings offer a knowledge base for the development of novel prevention and treatment methods that are independent of the immune system.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

The pandemic caused by the SARS-CoV-2 virus has claimed more than 6.5 million lives worldwide. This global challenge has led to accelerated development of highly effective vaccines tied to their ability to elicit a sustained immune response. While numerous studies have focused primarily on the spike (S) protein, less is known about the interior of the virus. Here we propose a methodology that combines several experimental and simulation techniques to elucidate the internal structure and mechanical properties of the SARS-CoV-2 virus. The mechanical response of the virus was analyzed by nanoindentation tests using a novel flat indenter and evaluated in comparison to a conventional sharp tip indentation. The elastic properties of the viral membrane were estimated by analytical solutions, molecular dynamics (MD) simulations on a membrane patch and by a 3D Finite Element (FE)-beam model of the virion's spike protein and membrane molecular structure. The FE-based inverse engineering approach provided a reasonable reproduction of the mechanical response of the virus from the sharp tip indentation and was successfully verified against the flat tip indentation results. The elastic modulus of the viral membrane was estimated in the range of 7–20 MPa. MD simulations showed that the presence of proteins significantly reduces the fracture strength of the membrane patch. However, FE simulations revealed an overall high fracture strength of the virus, with a mechanical behavior similar to the highly ductile behavior of engineering metallic materials. The failure mechanics of the membrane during sharp tip indentation includes progressive damage combined with localized collapse of the membrane due to severe bending. Furthermore, the results support the hypothesis of a close association of the long membrane proteins (M) with membrane-bound hexagonally packed ribonucleoproteins (RNPs). Beyond improved understanding of coronavirus structure, the present findings offer a knowledge base for the development of novel prevention and treatment methods that are independent of the immune system. |

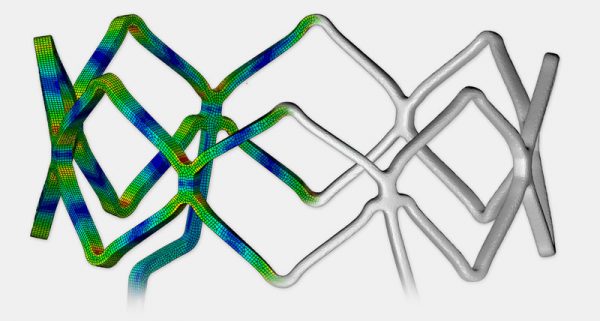

Wiesent, L.; Stocker, F.; Nonn, A. Investigating the influence of geometric parameters on the deformation of laser powder bed fused stents using low-fidelity thermo-mechanical analysis Werkstoffsimulation Artikel In: Materialia, Bd. 28, S. 101774, 2023, ISSN: 2589-1529. @article{WIESENT2023101774,

title = {Investigating the influence of geometric parameters on the deformation of laser powder bed fused stents using low-fidelity thermo-mechanical analysis},

author = {L. Wiesent and F. Stocker and A. Nonn},

url = {https://www.sciencedirect.com/science/article/pii/S2589152923001011},

doi = {https://doi.org/10.1016/j.mtla.2023.101774},

issn = {2589-1529},

year = {2023},

date = {2023-01-01},

urldate = {2023-01-01},

journal = {Materialia},

volume = {28},

pages = {101774},

abstract = {Maintaining dimensional accuracy is a major challenge of laser powder bed fusion (L-PBF) preventing its application for more complex and filigree L-PBF structures in industrial practice. Previous studies have shown that residual stresses and distortion of benchmark L-PBF components may be predicted by sequential thermo-mechanical analyses. However, the reliability of these analyses for more complex structures must be critically questioned, as comprehensive validation and sensitivity analyses are scarce. In this paper, we present a calibrated and validated low-fidelity sequential thermo-mechanical finite element analysis (FEA) of a tubular L-PBF lattice structure, i.e., an aortic stent, where pronounced local deformation is expected. As a first step, the finite element model was extensively calibrated using experimental data to ensure reproducibility of the simulation results. Thereupon, geometric features critical to the distortion of L-PBF lattice structures and measures to compensate for the distortion, such as inversion of the distorted L-PBF structure, were investigated. It was found that the distortion of the L-PBF lattice structures can be reduced, but not completely prevented, by increasing the strut angles, increasing the strut thickness, and decreasing the transition radius in the area of merging struts. FEA-based inversion of the numerically predicted deformed structure minimized distortion, resulting in the L-PBF aortic stent approximating the intended CAD geometry even with a small strut thickness. This work shows that low-fidelity sequential thermo-mechanical FEA can be used not only for the analysis and deformation compensation of reference structures, but also for the analysis of more complex filigree structures with pronounced local deformation.},

keywords = {},

pubstate = {published},

tppubtype = {article}

}

Maintaining dimensional accuracy is a major challenge of laser powder bed fusion (L-PBF) preventing its application for more complex and filigree L-PBF structures in industrial practice. Previous studies have shown that residual stresses and distortion of benchmark L-PBF components may be predicted by sequential thermo-mechanical analyses. However, the reliability of these analyses for more complex structures must be critically questioned, as comprehensive validation and sensitivity analyses are scarce. In this paper, we present a calibrated and validated low-fidelity sequential thermo-mechanical finite element analysis (FEA) of a tubular L-PBF lattice structure, i.e., an aortic stent, where pronounced local deformation is expected. As a first step, the finite element model was extensively calibrated using experimental data to ensure reproducibility of the simulation results. Thereupon, geometric features critical to the distortion of L-PBF lattice structures and measures to compensate for the distortion, such as inversion of the distorted L-PBF structure, were investigated. It was found that the distortion of the L-PBF lattice structures can be reduced, but not completely prevented, by increasing the strut angles, increasing the strut thickness, and decreasing the transition radius in the area of merging struts. FEA-based inversion of the numerically predicted deformed structure minimized distortion, resulting in the L-PBF aortic stent approximating the intended CAD geometry even with a small strut thickness. This work shows that low-fidelity sequential thermo-mechanical FEA can be used not only for the analysis and deformation compensation of reference structures, but also for the analysis of more complex filigree structures with pronounced local deformation. |