Leichtbau

Das Labor für Faserverbundtechnik (LFT) der Fakultät Maschinenbau an der OTH Regensburg konnte bereits in zahlreichen Forschungs- und Entwicklungsaufträgen, sowie bei Schadensanalysen für die Wirtschaft das Wissen aus der Lehre und Forschung in die Praxis transportieren, um den Unternehmen einen Entwicklungs- und Wettbewerbsvorteil zu bieten. Diese Erfahrung und Praxis wird nun in den Technologie Campus Neustadt an der Donau eingebracht und erweitert.

Neben der Auslegung klassischer isotroper Werkstoffe und Systeme im Sinne des System- und Strukturleichtbau durch u. a. Topologie-Optimierungen und Funktionsintegrationen widmet sich der Bereich Leichtbau vor allem dem Stoffleichtbau.

Vor allem faserverstärkte Kunststoffe (FVK) zeichnen sich im technischen Bereich durch ihre sehr guten spezifischen Steifigkeiten und Festigkeiten aus. Neben dem meist bekannten kohlenstofffaserverstärkten Kunststoff, auch CFK oder umgangssprachlich nur Carbon genannt, sind vor allem Glasfaser-, Aramidfaser- oder auch Basaltfaserverbunde weitere technisch interessante Beispiele von faserverstärkten Werkstoffen. Nicht nur die Gewichtsoptimierung sondern weitere Materialeigenschaften wie die Einstellbarkeit der elektrischen Eigenschaften, die elastischen Eigenschaften oder die Beständigkeiten gegenüber Medien und Alterung sind einige Punkte für die Anwendung solcher Materialien.

Dem Einsatz gegenüber stehen häufig Unsicherheiten in Bezug auf die Kosten und den Aufwand in der Herstellung und Verwendung solcher Werkstoffe. Auch die wenig verbreitete Kenntnis zum fasergerechten Konstruieren und Fertigen spielt in dieser Hinsicht eine Rolle.

Aufgabenfelder

Leistungen

Fertigungsverfahren

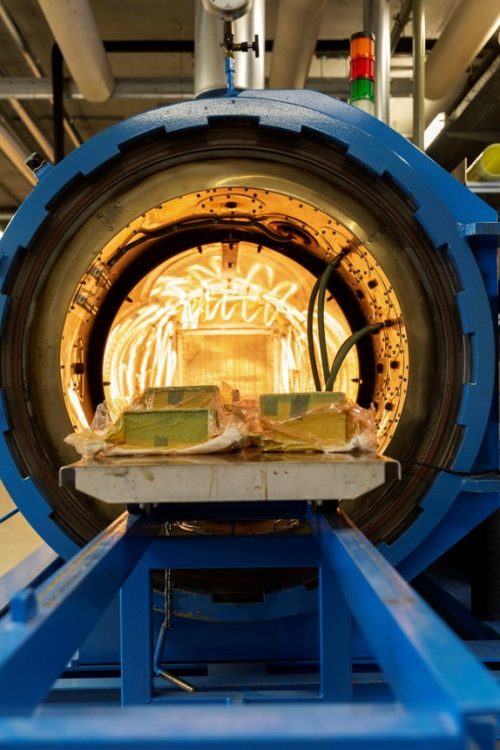

- Heißluftautoklavtechnik mit und ohne Prepreg-Systemen

- Vakuuminfusion- und Handlaminierverfahren mit unterschiedlichen Oberflächeneigenschaften

- Wickelverfahren mit eigenen Anlagen für duroplastische und thermoplastische Matrixsysteme

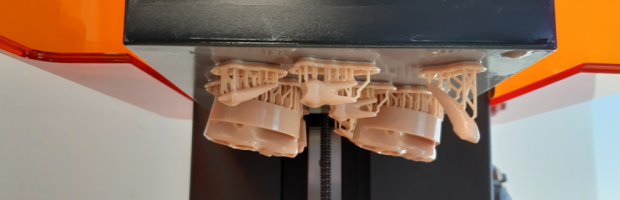

- 3D-Druckverfahren auf Basis des FDM- und SLA-Verfahrens mit und ohne Faserverstärkung in Kurz-, Lang- und Endlosform

Technische Entwicklung/Konstruktion

- Problemanalyse mit Ausarbeitung der Anforderungen

- Erarbeitung von Prinziplösungen und -ideen

- Konzepterstellung mit skizzierten Entwürfen

- Auslegung und Berechnung des Entwurfs

- Ausarbeitung in CAD-Programmen

- Zeichnungsableitung und Fertigungsbegleitung

Bauteilversuch

- Versuchsplanung mit Beachtung der Anforderungen

- Vorrichtungsbau zur Adaption von Krafteinleitung und Befestigung

- Auslegung und Anbringung der Messtechnik (DMS, DIC, etc.)

- Durchführung der Versuche unter Laborbedingungen

- Aufbereitung und Auswertung der Messdaten

Werkstoff- und Materialanalyse

- Kennwertermittlungen

- Festigkeitsprüfungen

- Zug-, Druck-, Biege- und Schublast

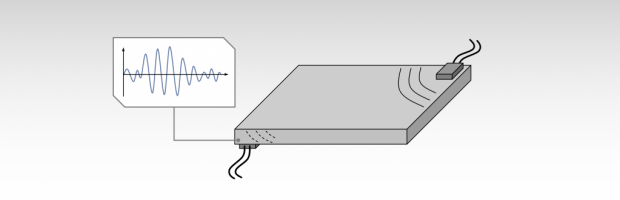

- Ultraschallprüfung

- Mikroskopie

- Faser- und Porenvolumengehaltsbestimmung

- Frequenz- und Schwingungsverhalten

- Thermisches Verhalten

Berechnung und Simulation

- Auslegung von Baugruppen, Bauteilen und Werkstoffen

- Festigkeitsnachweis eizelner Bauteile oder Werkstoffe mit Kennwertermittlung

- Analytische Modelle von Teilsystemen wie Bögen, Rohre oder Platten

- Klassische Berechnung von FVK anhand von Laminattheorien

- Numerische Abbildung von FVK in mechanischen Analysen

- Zyklische Bauteilbelastungen im Sinne von Fatigue und Lebensdauerberechnung

Beratung und Dienstleistung

- Prozess- und Schadensanalyse

- Berechnungs- und Fertigungsberatung

- Fachvorträge in Unternehmen

- Seminare und Schulungen der Industrie

Materialien und Fragestellungen

Materialien

- Stahl- und Aluminiumlegierungen aus diversen Herstellungsprozessen

- Thermoplastische und Duroplastische Kunststoffe

- Kurz- und Langfaserverstärkte Kunststoffe

- Endlosfaserverstärkte Kunststoffe mit Fasern aus Glas, Kohlenstoff, Basalt oder Aramid und beliebiger Kunststoffmatrix

Typische Fragen

- Welche Ausgangsmaterialien an Faser- und Kunststoff benötige ich für die vorhandenen Anforderungen?

- Welche Bauteildimensionen, Faserorientierungen und Lagenaufbauten benötige ich?

- Wie viel Gewichtsersparnis liefert mir der Werkstoffwechsel in Relation zu den Mehrkosten?

- Wie kann das Bauteil aus FVK gefertigt werden?

- Welche Materialeigenschaften liegen in dem FVK-Bauteil vor und wie kann ich diese bestimmen?

- Unter welchen Lastbedingungen tritt ein Erst- und Endversagen der Struktur auf und wie kann ich dies verhindern bzw. feststellen?

- Wie simuliere ich Bauteile aus FVK?

- Wie ist das Langzeitverhalten von FVK?

Branchen

Ressourcen

3D-Drucker + Faserverstärkung

Differential Scanning Calorimeter

Heißluftautoklav

Projekte

HILITES

EcoBuggy

Publikationen

2014 |

The influence of ondulations in fabric reinforced layers on the damping properties of fibre-reinforced plastics Leichtbau Proceedings Article In: Ziemann, O.; Mottok, J.; Pforr, J. (Hrsg.): Applied Research Conference 2014 – ARC 2014, S. 306–310, Ostbayerische Technische Hochschule Regensburg Shaker-Verlag, 2014, ISBN: 978-3844028751. |

Experimental investigation of energy dissipation properties of fibre reinforced plastics with hybrid layups under high-velocity impact loads. Leichtbau Artikel In: Journal of Achievements in Materials and Manufacturing Engineering (JAMME), Bd. 64, Nr. 1, S. 14–20, 2014. |

Mechanical characterization of basalt woven fabric composites: numerical and experimental investigation. Leichtbau Artikel In: Frattura ed Integrità Strutturale (Fracture and Structural Integrity), Bd. 8, Nr. 28, S. 1-11, 2014, ISSN: 1971-8993. |

Experimental investigation of damping properties of unidirectionally and fabric reinforced plastics by the free decay method Leichtbau Artikel In: Journal of Achievements in Materials and Manufacturing Engineering (JAMME), Bd. 63, Nr. 2, S. 65-80, 2014, ISSN: 1734-8412. |

Muskuloskelettale Simulation zur Untersuchung des Einflusses geometrischer Parameter der Wirbelkörper auf die Belastung der Lendenwirbelsäule. Leichtbau Forschungsbericht Ostbayerische Hochschule Regensburg inixmedia GmbH Marketing & Medienberatung, Forschungsbericht 2013, 2014. |